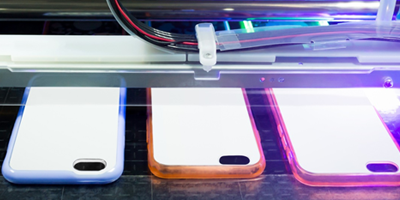

Faster curing with impressive printing on any surface

For the truly challenging printing and coating applications on tricky surfaces, cationic curing is the answer. Cationic curing helps you meet the highest demands on adhesion, low migration and final print quality.

To optimize your cationic formulation, you need the best building blocks. As a global leader in innovative and sustainable core components for cationic curing, we have the technology and expertise to support you all the way. Perstorp products offer low viscosity for optimal end-quality and faster curing speed, improving productivity and cost-effectiveness. Applications include 3D-printing, food packaging, can coating and shrink sleeves.

Three key drivers for using cationic curing are:

- Product quality and performance – excellent adhesion on difficult substrates, low shrinkage, hardness, flexibility and chemical resistance.

- Increased productivity - as a result of the fast-curing process and no oxygen inhibition

- Cost-effectiveness – thanks to higher productivity and lower other processing costs such as lower energy consumption and absence of solvent solutions.

The Curalite™ product family

Our oxetane Curalite™ combines increased reactivity with good diluting power of epoxy resins making processing faster and boosting productivity. Curalite™ can also improve a formulations’ through-cure, adhesion and chemical resistance. This makes Curalite™ the reactive diluent of choice for difficult printing surfaces if you want to prevent delamination and maintain a high-quality appearance. Curalite™ is also safe to use for food packaging, as it offers fewer migration issues and no residual odor.

Reduce your carbon footprint

Perstorp can help you fulfil your greenhouse gas reduction targets by offering products with a lower carbon footprint. Curalite™ Pro is chemically identical to its fossil counterpart, offering the same quality without trade-off in performance. The only difference lies in the raw materials, whose origins are renewable/recycled instead of virgin fossil.

We are always open to collaborations with innovation partners to fine-tune properties, develop new cationic formulas and help you to lower your carbon footprint.