Develop the best UV/EB curable monomers & oligomers

Perstorp offers a broad range of products for traditional free radical UV/EB curing as well as cationic UV curing technologies. Our products are designed to meet the needs of industry, society and the environment.

Perstorp RadCure aims to make curing processes safer, faster, more profitable and measurably more sustainable. We want to help you make your curing processes VOC-free, more reactive, and deliver greater surface resilience with low migration.

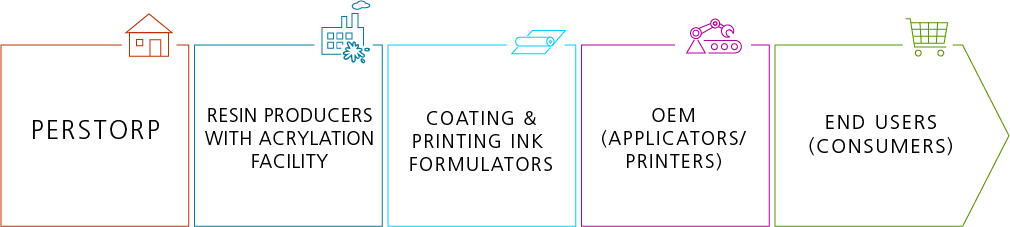

We are involved at many stages of innovation throughout the supply chain and are keen to talk with anybody who is as committed as we are to grow knowledge on the technologies and applications of radiation curing.

Free radical UV/EB curing

Perstorp building blocks for free radical UV/EB curing are used to develop high-performing monomers and oligomers offering low viscosity and high reactivity to increase line-speed. They have a unique NEO-structure (no β-hydrogens) which increases the yield during esterification and reduces the ageing of the finished monomer/oligomer. Additional benefits of our RadCure product portfolio include:

- Reduced carbon footprint with our Pro-Environment grades

- Broad portfolio of alkoxylates to tailor properties to your needs

- An experienced partner with extensive knowledge in the industry

Perstorp products for UV/EB curing contribute to high-performance formulations for a variety of applications such as:

- Wooden flooring & furniture

- Printing inks & OPV (Over Print Varnish) for packaging

- Electronics & adhesives

- SLA 3D-printing

- Coatings for a variety of substrates such as metals, plastics and glass.

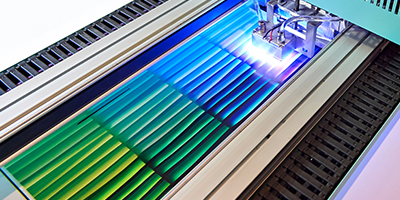

Cationic curing

For the truly challenging printing and coating applications on tricky surfaces, cationic curing is the answer. Cationic curing helps you meet the highest demands on adhesion, low migration and final print quality.