Why your choice of water additive matters: a conclusive customer case

There is no silver bullet that can help control Salmonella in poultry production. It requires a full toolbox that is strategically applied for optimal results. One of the tools in this toolbox may be the use of liquid products applied via the water in the last days of broiler production. These products can support the management of the incidence of Salmonella contamination and transfer to the processing plants. But even then product quality and efficacy matters! Not all solutions are equal. Have you ever tried to cut through solid piece of wood with the cheapest handsaw on the shelve? Not recommended. So equip your toolbox with effective tools for optimal results. Fortunately one of our customers in the Midwest of the US has a flexible set-up that allowed for testing with different solutions over time, allowing for the results to be compared.

Salmonellosis: the antagonist of food safety

Globally it is estimated that almost 94 million cases of salmonella poisoning are registered every year. That makes it enemy number 1 in the struggle for food safety. Poultry meat and eggs are some of the most commonly linked food products linked to salmonellosis outbreaks. New control measures to reduce the impact of this bacterium on global health are constantly being implemented by countries and regions: and with clear effects. However that doesn’t mean it is always easy to meet these requirements when you are poultry production professional.

An often overlooked tool: water hygiene

Successful control programs consider the whole poultry production pyramid - starting from breeders down to broilers and even all the incoming feed materials, water and other materials used during production. One of the tools available to manage the incidence of Salmonella in your poultry is the use of liquid products in the last days of broiler production via water that aim to manage the incidence of Salmonella intestinal contamination and transfer to the processing plants.

A case worth sharing

An integrator in the Midwest of the US was observing increased Salmonella in their production. They self-monitor in order to ensure meeting the FSIS (Food Safety and Inspection Service) directive’s requirement of a maximum of 9.8% positive carcasses to maintain a Category 2 status (half of that for a Category 1 status; in which producers aim for). During processing of the birds, they follow and pull birds from each production house, do carcass wash’s and subsequently analyzed them for the presence of the pathogen. The FSIS guideline proved challenging to adhere to.

A/B testing at its finest

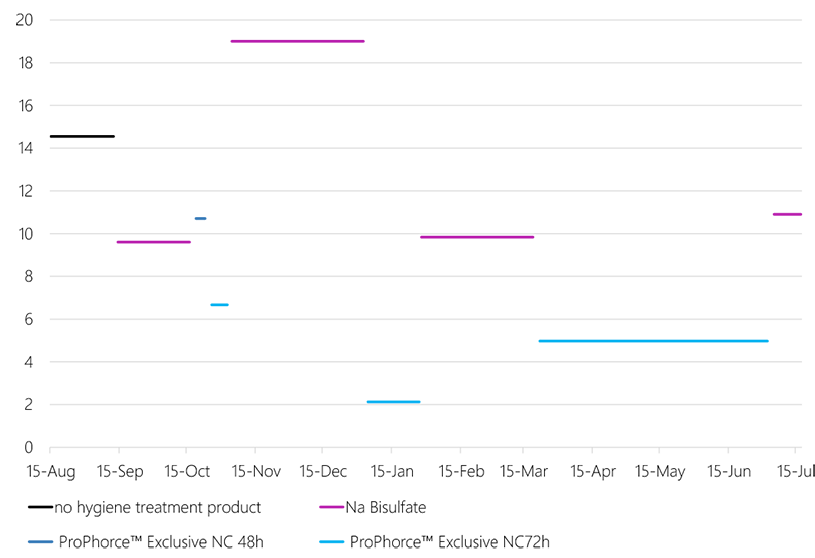

The customer wanted to try ProPhorce™ Exclusive NC (an organic acid based liquid product with addition of a phytochemical compound) to compare it to sodium bisulphate based product they were using at the time. The product delivered to the animals via drinking water prior to slaughter. In the period between mid-2020 and mid-2021 they intermittently used both products. The immediate results they saw when using ProPhorce™ Exclusive NC were validated repeatedly by reverting back to sodium bisulphate. This proved that results were not due to coincidental internal pathogen reductions but were directly related to the choice of product used in the water. What better way to do practical A/B testing? A diary:

October 2020

ProPhorce™ Exclusive NC was tested for one week 48 hours prior to slaughter. As the results weren’t immediately apparent, the application time was increased to 72 hours before slaughter for another two weeks following this period (see graph). It was in this period that a clear reduction of Salmonella positive birds was observed: below the 8% which seemed so elusive before.

November 2020

After the trial period, the integrator reverted to sodium bisulphate for 8 weeks from November 2020 to January 2021. The Salmonella positive incidence increased to over 18%.

January – March 2021

In January 2021 the processing plant introduced additional measures to control salmonella. During this time a second trial was started which again tested both products consecutively. Results once again favored ProPhorce™ Exclusive NC in the water for 72 hours before slaughter.

March – July 2021

A third, longer trial, was conducted with ProPhorce™ Exclusive NC in the water for 72 hours before slaughter. Again, salmonella levels were improved, and then levels increased again when ProPhorce™ Exclusive NC was removed for 2 weeks in July. This producer is still using ProPhorce™ Exclusive NC to this date.

In conclusion

Thanks to ProPhorce™ Exclusive NC the percentage of Salmonella positives was reported at 4.97% on average: a remarkable reduction of 48.1% compared to the baseline results during the entire period from August 2020 to July 2021. In this operation the product was clearly able to control the Salmonella contamination of broiler carcasses.

References available on request.