The importance of keeping cool when feeding TMR - part 2

In part 1 of this article, you learned that when all the elements of the diet are mixed together in the TMR, the cows receive a balanced diet with each bite. However, there are unwanted microorganisms in the TMR, known as aerobic spoilage, that can reduce the feed's nutritive value and palatability. The rising temperature of the TMR causes more unwanted fermentation.

How to manage the temperature in the TMR?

There are various strategies that help control the temperature of the TMR including:

- Avoid feeding during the warmest hours of the day

- Feed twice per day if possible, delivering the larger portion of the feed in the evening

- Actively manage the silage clamp or bunker, using material at the face each day

- Avoid adding green forage material which would increase the moisture content

- Make sure sprinklers or other water-based cooling systems in the barn are used away from the feeding area to prevent increasing the moisture content

- Add a preservative such as ProMyr™ TMR Cool, ProMyr™ TMR Solid or ProMyr™ TMR Flexible to the ration. Available in dry (ProMyr™ TMR Cool and ProMyr™ TMR Solid) and liquid (ProMyr™ TMR Flexible) forms to suit the requirements of each unique farm, ProMyr™ TMR controls the temperature of the TMR for longer, stabilizing the feed and reducing spoilage.

TMR preservation with ProMyr™ TMR

ProMyr™ TMR is a synergistic blend of salts and/or organic acids used to control a wide variety of microorganisms. The product works by inhibiting the growth of a broad spectrum of unwanted microorganisms, therefore stabilizing the ration, maintaining palatability, and ensuring consistent feed intakes.

Available in dry (ProMyr™ TMR Cool and ProMyr™ TMR Solid) and liquid (ProMyr™ TMR Flexible) forms to suit the requirements of each unique farm, ProMyr™ TMR controls the temperature of the TMR for longer, stabilizing the feed and reducing spoilage.

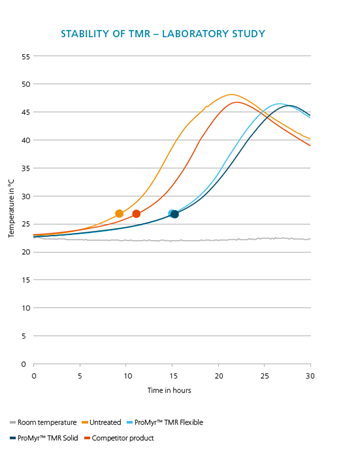

Figure 2 shows the results of a laboratory study in which samples of TMR were monitored for temperature increases over time. The sample without a preservative product reached 27 oC after 9 hours. In comparison, the samples treated with ProMyr™ TMR (Solid and Flexible) reached 27 oC after 15 hours. This additional 6 hours of time translates to a big difference in terms of nutritional value and palatability.

Figure 2. Temperature rise in TMR samples with and without a preservative product

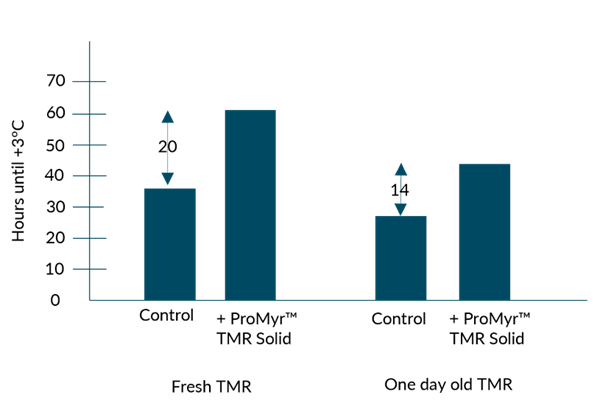

A similar study was conducted at the Swedish University of Agricultural Sciences using fresh and one-day-old TMR samples (Figure 3). Adding ProMyr™ TMR to one-day-old TMR extended the time it took for the temperature to increase by three degrees by 14 hours. And in the fresh TMR sample, ProMyr™ TMR extended the time before the three-degree temperature rise by 20 hours. In practice, this means the temperature of the TMR would not increase while it was in front of the animals, therefore reducing unwanted fermentation, and maintaining nutritional value, palatability and feed intake levels. The benefits this delivers in terms of animal performance can be seen in Table 1.

Figure 3. ProMyr™ maintains TMR temperature for longer

Table 1. Performance results of cows fed TMR treated with ProMyr™ TMR Solid compared to a control group

|

Control |

ProMyr™ TMR Solid |

|

|

Milk yield (kg/day) |

35.4 |

35.8 |

|

ECM* (kg/day) |

36.4 |

37.4 |

|

Fat (%) |

4.33 |

4.44 |

|

Protein (%) |

3.45 |

3.47 |

|

Lactose (%) |

4.46 |

4.49 |

In the same Swedish trial, milk yield and energy corrected milk (ECM) were numerically improved when ProMyr™ TMR Solid was added to the TMR. These improvements were achieved at a lower dry matter intake (DMI) level (24.6 kg/day in the control group compared to 23.2 in the ProMyr™ TMR Solid group), equating to an improvement in the ECM: DMI ratio by 0.1 percentage points.

In another trial conducted at São Paulo University in Brazil, the same numerical improvements in milk yield were observed. The rations were examined to calculate the sorting index which showed a significant difference in material measuring 8-19 mm in length in the control group compared to the ProMyr™ TMR Solid group. The cows that received the TMR with ProMyr™ TMR Solid decreased selection for this particle size, highlighting that there was less sorting of the feed.

Conclusion

Feeding dairy cows with a TMR is an effective and efficient way to deliver all the nutrients the animal needs for optimal milk production. But care must be taken to ensure the quality of the TMR remains high while the feed is present in front of the animal. TMRs provide the perfect combination of nutrients, moisture, and oxygen which encourages the growth of microorganisms. This growth and unwanted fermentation will cause the feed quality to deteriorate, and the palatability of the feed to drop. Feed refusals will result, and the performance and milk production of the herd will suffer.

Adding a preservative such as ProMyr™ TMR will control the growth of microorganisms and stabilize the temperature of the feed while it is in front of the animal. This will prevent spoilage from unwanted fermentation, maintain intake levels and ensure the productivity of the herd.

Contact your Perstorp area representative for more information.