In-depth proof of the C10 plasticizer advantages

Learn more about the significant performance advantages that Perstorp's C10 plasticizers offer.

C10 plasticizers gives an extended, more sustainable and trouble-free life

C10 plasticizers’ unique chemical and mechanical properties make them an outstanding choice for PVC products requiring long-life durability and performance reliability. Where these demands occur, it is difficult to substitute DPHP or DIDP with C8-9 plasticizers. C10 plasticizers offer proven advantages, particularly DPHP in weather resistance, exceptional flexibility, and overall wear and tear. This facilitates sustainable and low maintenance solutions for tough outdoor applications.

The advantages become evident when looking at the direct performance comparisons between C10 and C8-9 plasticizers. Below is the performance data relating to the 7 advantages of C10 plasticizers cited in a previous article. For comparison, we have chosen DINP and the once widely used DOP, which is now a classified plasticizer.

Long-life durability and greater sustainability

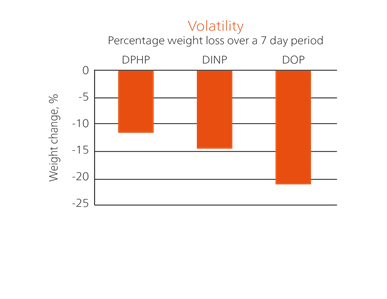

As a combination, the characteristics of softness, flexibility, and durability appear to be rather contradictory, but that is precisely the performance standard C10 plasticizers achieve. Underpinning this is the exceptionally low volatility and the resistance to degradation in PVC compounds operating at high or elevated temperatures. Graph 1 confirms the low volatility in terms of weight loss over 7 days at elevated temperatures, which clearly shows that DPHP loses approximately 50% less weight than DOP and 17% less weight than DINP. This low volatility provides the product with the durability, sustainability, and mechanical property retention needed to promote a long and trouble-free life.

In particular, cable and electrical wire manufacturers favor C10 plasticizers because of their long-life span and their ability to operate safely at high temperatures. This performance reliability avoids expensive maintenance and service issues, especially with underground cables.

DPHP’s ability to easily form and shape due to its great flexibility is another key reason why it is preferred in the PVC insulation of cables and wire. Being able to twist and bend without cracking is a primary safety demand, and in this respect, C10 plasticizers are the best at minimizing the risk.

Weather resistance

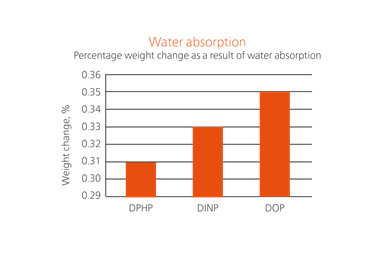

A good measure of weather resistance is the plasticizer’s ability to resist absorbing water and the effects of UV, which can degrade both the performance and aesthetics, leading to higher maintenance costs and early replacement.

In Graph 2, the C10 plasticizer not only offers low water absorption properties but also is significantly better than the competitive plasticizers sampled. This ability to prevent the ingress of water becomes vital in PVC products if they are to survive harsh outdoor conditions over many years.

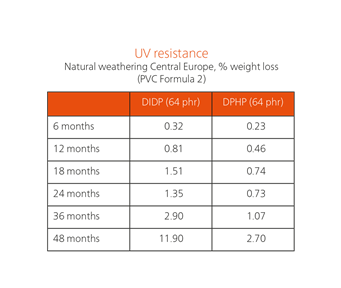

DPHP, in particular, provides impressive UV resistance to prolonged sunlight without degrading or breaking down. This ensures the mechanical properties of the PVC are retained across the lifetime of the product. The ability to resist aging added to low water absorption makes C10 plasticizers the premier choice for roofing membranes used in sporting arenas, industrial facilities, commercial, and residential buildings. The weather resistance properties of DPHP contribute directly to product sustainability by extending its useful life.

Safe and secure environment

C10 plasticizers are preferred in cables for safety reasons. Their exceptional low water absorption maintains the cable’s isolation properties, thus preventing the risk of electrical shock.

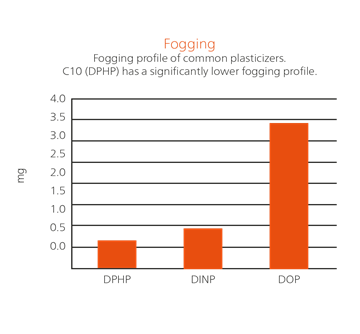

C10s are also known for their anti-fogging or low fogging capabilities, which is due to the exceptionally low volatility. This makes C10 plasticizers particularly suitable for car interiors. As Graph 3, highlights DPHP has a significantly lower fogging profile than C8-9 alternatives, especially against DOP.

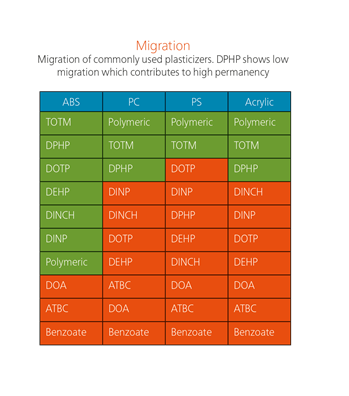

Additionally, low migration contributes to high permanency, and as can be seen in Table 2, DPHP is highly suitable for ABS, PC, and acrylic plastics. DPHP has been tested toxicologically and is safe to use and handle. It was one of the first plasticizers registered under the European chemicals regulation REACH and is non-classified.

Smooth and productive processing

In terms of processing, a DPHP plasticizer is easy to switch to from C8-9 plasticizers and even as an alternative for DIDP because only minor compound changes are necessary in cable formulations, for example. The lower density of DPHP, compared with C8-9 plasticizers, provides PVC compounders with the opportunity to increase extrusion rates, and contribute to a greater number of square meters of product.

Adding lifetime value to PVC products & applications

C10 plasticizers are premium general-purpose plasticizers that add real value to a wide range of PVC products and applications. The underlying durability and reliability, due to the chemistry and mechanical properties, extend the life span of products mainly in tough environments. This extension of life and lower maintenance requirements contribute to the sustainability of the application or product, helping to reduce both the carbon and cost footprints. In effect, a win-win for business and the environment.

The high-performance reasons for choosing C10 plasticizers - low volatility, water absorption, fogging, migration, UV/aging, density, and non-classified - give a wide range of opportunities to compounders, extrusion, and calendaring operators when developing their PVC compounds. Ultimately product performance and reliability with low risk attached are sought in premium applications, such as cables, roofing membranes, and automotive interiors. And that is where C10 plasticizers win both in the short and long term.

For more information about this article or plasticizers contact Anders Magnusson.