HS Number: 230990

ProPhorce™ SA products offer:

• Effective antibacterial decontamination

• Assistance with enterobacterial reduction

• Efficient decontamination when used with heat treatments

According to international rules the feed industry is obligated to supply salmonella free feedstuffs. Enterobacteria and salmonella are a potential risk to feed. The safety of feed is highly important as contaminated feed can lead to reduced performance. Feed safety begins with a clean production system. From the farmer to the feed producer, all partners need to operate in a safe and clean way. Each of the links in the chain may affect the safety of our feed. By systematically checking all production stages including purchasing, processing, and distribution, feed producers strive to reduce enterobacteria.

Pioneer in pathogen mitigation

Research has shown that elimination of enterobacteria cannot be ensured despite precautions and systematic checking. Perstorp is a pioneer when it comes to feed hygiene. Our widespread experience and trials over the years have shown the synergy between heat treatment and the use of ProPhorce™ SA.

The considered acceptable enterobacteria load in any classical compound feed is <4log CFU/g. While it is mandatory to fulfill <2log CFU/g in breeding layer feed.

For many years, heat conditioning (80°C, 2min) was considered the most efficient way to control the enterobacteria load in compound feed.

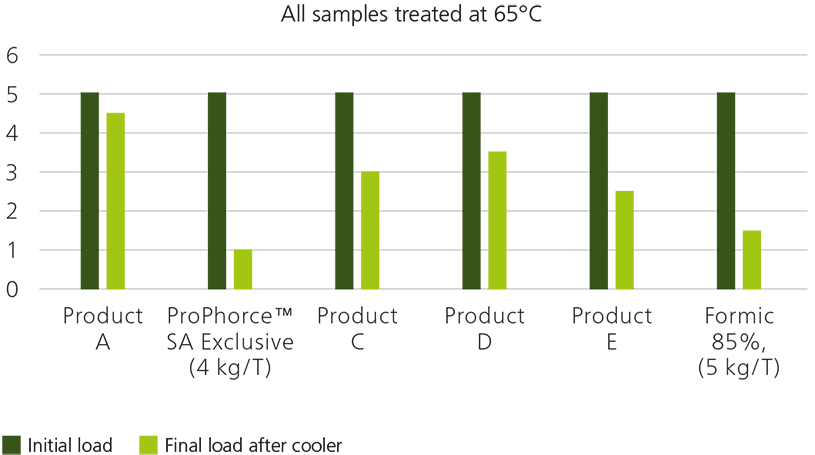

The SYTTAC study (Tecaliman, 2012) showed a synergy between reduced heat conditioning (65°C, 2min) and organic acid solutions, some organic acid recipes being more efficient than others. In this study, a very high enterobacteria inoculation was operated (>5log). (Graph 1).

Graph 1: Comparison between ProPhorce™ SA Exclusive and 4 competition recipes and formic acid 85% in mash feed (entero load log CFU/g)

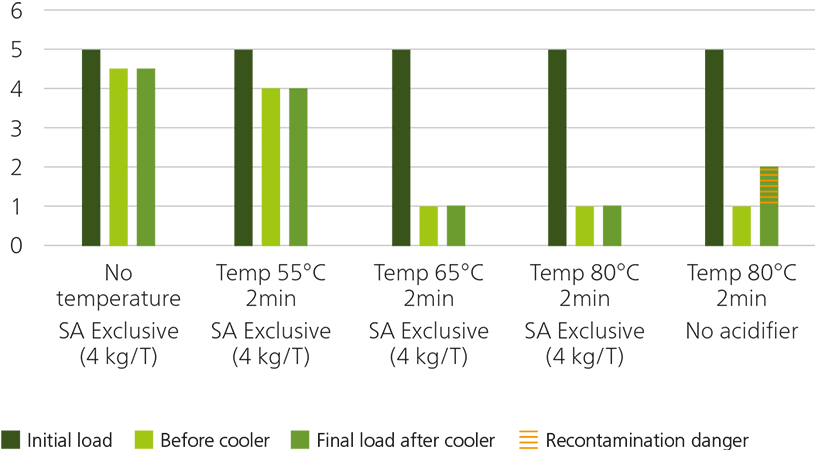

In feed production, heat conditioning is common practice, while during the cooling-drying phase recontamination risks arise.

The SYTTAC study (Tecaliman, 2012) and our control plans show that ProPhorce™ SA solutions help to prevent the feed from being recontaminated by enterobacteria from unknown origin. (Graph 2)

Combined ProPhorce™ SA Exclusive and temperature efficiency in mash feed (entero load in log CFU/g).