Market Perspective: Flexible PVC – A Sustainable Material

Flexible PVC is characterized by its excellent cost performance ratio and can be found in many of the articles that surrounds us on a daily basis. It can help keeping the hygienic standards at hospitals, replacing leather in jackets, handbags and car seats, and it helps increasing the life-time of cables. But now, the material also offers an opportunity to move away from fossil based raw materials, improving the environmental credentials even more!

Flexible PVC in the world we live, play and work

PVC is one of the most commonly produced plastics in the world and is essential in our everyday lives. To make PVC flexible, a plasticizer is added to make it soft and bendable. Flexible PVC is a very durable and cost efficient material that is being used for a variety of applications ranging from cable insulations and vinyl flooring to artificial leather and automotive interiors. It is also a very commonly used material in the healthcare sector due to hygienic reasons. The material was under scrutiny some years back and all the traction that PVC has got, in combination with improved production methods, developed chemistry and more stringent legislation, has led to positive movements by the industry; additives and plasticizers have been improved from an environmental and safety perspective, heavy metals have been phased out and the market for non-phthalate plasticizers is constantly growing.

Non-phthalate plasticizers

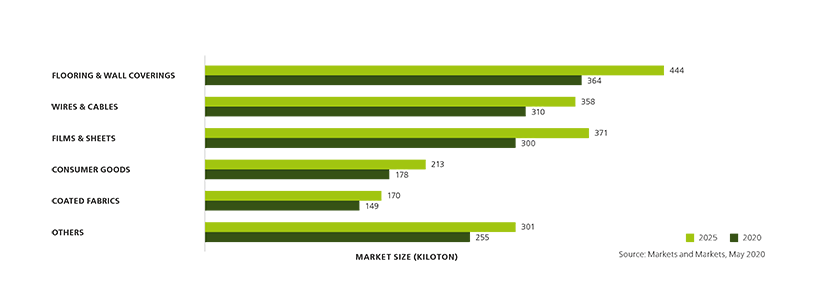

To put it simple; the lion share of the non-phthalate plasticizer market can be found in application areas that are close to consumers; like flooring & wall covering, furniture, toys, food contact materials, and other types of consumer goods. This movement towards non-phthalate plasticizers has been obvious since a few years back, but recently the market players have started to actively search for more environmentally friendly alternatives, like bio-based or bio-attributed ingredients, to improve the environmental credentials of flexible PVC.

Making flexible PVC an even more sustainable material

The durability aspect of flexible PVC is in itself a sustainability aspect. Many of the products made by this material is expected to have a very long in-use life-time, retaining its qualities for decades. That means that the environmental impact will be spread out over many years, in some cases more than 50 years. However, since last year we are also starting to see movements towards fossil-free alternatives in the PVC market, e.g. bio-attributed* PVC grades offered by Vynova and Inovyn, and bio-based, as well as bio-attributed, plasticizers. The benefit of changing to a bio-attributed PVC, or plasticizer, is that they have identical molecular structures as their fossil-based counterparts. That means that they will have the same properties and consequently behave in the same way and no time-consuming and costly qualification process needs to be conducted. This enables companies to gradually shift to renewable alternatives with no additional investments in time or resources.