The importance of Feed Hygiene in Zinc Oxide reduction

Pharmacological doses of ZnO were commonly added to piglet diets to support gut health and reduce the incidence of PWD, reducing mortality rates and the long-term improved performance of the animal. However, that option is no longer available to pig producers.

The importance of Feed Hygiene in zinc oxide reduction

Why is Zinc oxide used in piglet diets?

Zinc oxide (ZnO) occurs naturally as the mineral zincite, but synthetic versions of ZnO are used in a variety of applications including animal nutrition. Although ZnO is not easily absorbed by the animal, many studies have shown that ZnO supplementation can:

- Improve fecal scores

- Reduce mortality rates

- Increase feed intake

- Improve nutrient digestibility and absorption

- Improve gut integrity

- Restore intestinal barrier function

- Reduce adhesion of E. coli to enterocytes

- Modulate the immune system

In swine production, the weaning stage is a very stressful time for a piglet due to the huge number of environmental, social, and nutritional changes that occur. These changes exert stress on the under-developed gastrointestinal and immune systems of the piglet, causing diseases such as post-weaning diarrhea (PWD).

Pharmacological doses of ZnO were commonly added to piglet diets to support gut health and reduce the incidence of PWD, reducing mortality rates and the long-term improved performance of the animal. However, that option is no longer available to pig producers.

The ban and the implications

While there are many benefits of using ZnO in feeds, there are also some much more significant disadvantages of its use including and not limited to:

- Increased resistance to antibiotics

- Decreased effectiveness and adsorption of other feed additives

- Detrimental effect on the environment

In 2017, the European Commission decided to remove approval for pharmacological doses of ZnO in pig feeds as the disadvantages of its use outweigh the benefits. The transition period to prepare for the removal of ZnO in pig diets ends in June 2022.

Without ZnO in the diet, producers could expect to see a drop in performance parameters such as body weight and feed intake, and an increase in mortality rate. So, what can be done to overcome this drop in performance?

Understanding PWD and piglet health

Unfortunately, there is no 'silver bullet' that can replace ZnO in piglet feeds to prevent PWD. The disease is caused by interactions between a number of factors such as:

- Environment

- Feed quality

- Bacteria

- Removal from sow

- Water quality

- New litter mates

- Management practices

Many of these factors can be controlled through improvements in management practices, biosecurity, health, and nutrition. Perstorp Weaning Winners program offers a range of solutions to support nutrition and performance. This article looks at biosecurity, and feed hygiene in particular, more closely.

Feed hygiene

Post-weaning diarrhea occurs when bacteria enter the piglet and takes advantage of the weakened immune system, proliferating in the gut. The bacteria involved are typically enterobacteria such as enterotoxigenic E. coli (ETEC). Bacterial contamination can come from a number of sources including other infected animals, personnel, vehicles, insects, water, and feed.

The safety of animal feed is highly important to prevent contamination. Once feed has arrived on site, it should be properly managed to ensure bacterial growth does not occur during storage, prior to feeding.

1. Raw material sourcing

Providing piglets with the best possible start in life is directly linked to their lifetime performance so piglet feeds are usually formulated using only the highest quality raw materials. There are many different component parts that make up a piglet ration, including cereals, proteins, fats, and additives. Contamination levels of all raw materials should be checked regularly to prevent infection, especially when new suppliers are used. Perstorp's feed hygiene monitoring service encourages customers to collect and send in samples for analysis. The results can help inform decisions about how best to manage any contamination in the feed.

2. Feed storage

Feed ingredients may be stored for long periods of time. Any contamination analysis might have been conducted weeks or months before the material is used. Feed silos provide the perfect environment for bacteria unless steps are taken to prevent bacterial growth.

3. Moisture content

Feed with a high moisture content is more palatable for the animal but is also more attractive to bacteria and molds. The combination of nutrients and moisture, when exposed to the air, provides the perfect conditions for pathogen growth. Removing water from the feed is not always possible so alternative methods of preventing contamination should be used.

ProPhorce™ SA

Delivering feed with a high nutritional value starts with selecting only the highest quality ingredients and ends with optimal preservation for the time it is stored. The risk of contamination is greatly reduced by making sure the feed is free from pathogens as soon as it arrives on farm.

ProPhorce™ SA is part of the Weaning Winners program, taking care of feed hygiene. ProPhorce™ SA is a range of complementary feeds, effective against pathogens even at low inclusion rates. Available in liquid or dry form, there is a ProPhorce™ SA solution to meet every requirement.

• ProPhorce™ SA Exclusive – liquid product containing essential oils and organic acids for optimal antibacterial effect.

• ProPhorce™ SA Special – versatile solution that can reduce bacterial pathogens and manage mold loads.

• ProPhorce™ SA Cleaning – dry product for optimal pathogen mitigation in feedstuffs, ingredients, and finished feeds. It can also be used for flushing critical contamination areas in feed mills.

• ProPhorce™ SA Flexible – a cost-effective solution to mitigate pathogens and manage mold loads that is also suitable for use in organic farming systems.

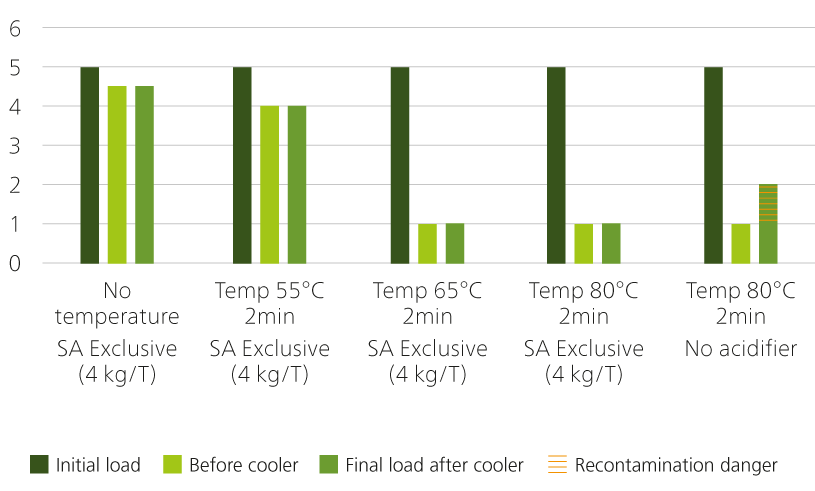

Numerous trials have shown the synergy between ProPhorce™ SA, and the heat treatment techniques typically used in feed processing. For many years, using heat was considered the most efficient way to control the enterobacteria load in feed. However, as shown in Figure 1, there is a risk of recontamination during the cooling-drying phase when ProPhorce™ SA is not included.

Figure 1. The effect of ProPhorce™ SA Exclusive and temperature conditioning on enterobacterial load in mash feed

Figure 1 shows that the biggest bacterial load reductions were seen when temperature conditioning was combined with ProPhorce™ SA Exclusive. The bacterial load was reduced before the cooler, and the reduction was maintained after cooling was complete, preventing any recontamination.

Pathogen mitigation to prevent PWD

Removing ZnO from piglet diets may leave some herds vulnerable to increased instances of PWD unless a holistic approach combining improvements in management practices, biosecurity, nutrition, and animal health are implemented. Preventing bacterial contamination from the feed and is the first line of defense against PWD and is easily managed using traditional heat conditioning combined with applying ProPhorce™ SA. And when used in combination with other products from Perstorp's Weaning Winners program, performance levels will be maintained even without ZnO in the diet.