Why you should focus on the optimal carrier for your PET and PC masterbatch

A very important but often overlooked factor in the development of masterbatches is the carrier material. Since the carrier is the base to which the additives and pigments are added, you can gain a lot by optimizing your choice of carrier.

Ease of processing

To enable good dispersion of the pigment or additive, you want your carrier to blend easily into the base polymer. You also want to be able to load the desired amount of the additive or pigment into the carrier. And if you are looking for cost efficiency, a more concentrated carrier minimizes the amount of masterbatch the converter has to add to the base polymer.

Retain key properties

To retain the key properties of your masterbatch, you need the carrier to have a minimum effect on the base polymer matrix. Take for example the transparency of polyester resins like PET and polycarbonate (PC). Anything added to the base polymer needs to have an excellent transparency in itself. And also full compatibility with the base polymer so you do not end up with haze or loss of clarity.

In PC resins, heat resistance is another key property that you do not want to compromise with additives. Many plastic parts utilizing PC polymer depend on its inherent high transparency as well as high heat resistance, for example in automotive applications.

Akestra™ - a masterbatch carrier

Finding polymers, that can function as a good carrier without compromising base polymers properties, can be a challenge. To overcome this challenge, Perstorp has introduced a completely new co-polyester called Akestra™ - a unique fully amorphous polyester with sparkling transparency and high heat resistance.

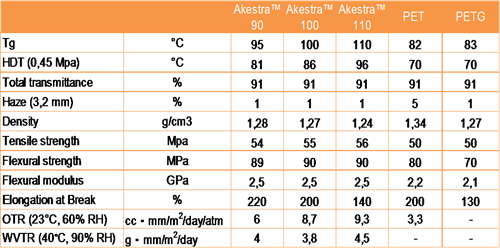

To accommodate different needs, Perstorp has made Akestra™ available in three different grades: Akestra™ 90, 100 and 110. Of these three grades, Akestra™ 90 has full miscibility in PET and PETG and is most suitable for polyester masterbatches. Akestra™ 100 and 110 are miscible with PC in all concentrations giving transparent blends, which make them suitable for polycarbonate masterbatches.

Low processing cost

High heat resistance and transparency are not the only benefits of using Akestra™ as a carrier in masterbatch. Other unique properties of Akestra™ are high melt strength and wide processing window, which makes it possible to add fillers to Akestra with retained melt properties. This enables fast and efficient processing in production.

Akestra™ can be processed at lower temperatures compared to crystalline polyesters and PC. This can be important to avoid thermal degradation of sensitive additives. Working at lower temperatures also means that less energy is required during processing of the masterbatch.

Increasing transparency in PET

Being a fully amorphous material Akestra™ not only ensures transparency when used in PET but it actually increases it. Issues with whitening at e.g. the injection point of PET articles due to the semi-crystalline nature of PET can be reduced and even completely removed by using as little as 10 to 20% of Akestra™ 90.

Reducing stress cracking in PC

Stress cracking in polycarbonate is a known inherent problem with articles made out of polycarbonate. After being subject to repeated tensile loading stress, cracking can compromise with the visual as well as mechanical properties of the PC part. In worst case, it can lead to fracture of the plastic part, which can have severe consequences in e.g. in automotive applications. Adding polyesters to PC is a known way to reduce the risk of stress cracking. However, as polyesters have much lower heat resistance than PC, an addition can reduce the heat resistance of the final material. Akestra™ 100 and 110 can be used in PC to improve processability giving no impact on transparency and with a very small effect on heat resistance.

Food contact applications

Akestra™ is fully approved for food contact use in Japan (JHOSPA), US (FDA) and EU (EC 10/2011). Hence Akestra™ is suitable also for masterbatches used in food packaging and other food contact applications.

Akestra™ is available in Europe only from Perstorp. Visit www.perstorp.com/akestra for more information.

By David Engberg, Product Manager, BU Specialty Polyols