RE-carbonizing chemicals: A key to a sustainable chemical industry

Almost all products that are crucial for our society, from medicines and clothing to appliances and mobile phones, cannot be manufactured without chemicals and carbon atoms as building blocks of the material. The problem is that basically all this carbon comes from virgin fossil sources, oil and gas, and is released into the atmosphere at the end of its life. Globally, the chemicals sector accounts for 14 percent of the industrial greenhouse gas emissions.

For this reason, and growing global scrutiny of plastic pollution, resource depletion and waste, the shift toward a circular economy is accelerating. Governments worldwide are strengthening regulations, recycled-content requirements, and single-use plastic restrictions, driving companies to rethink how materials are designed, produced, used, and recovered. In parallel, global and local policy shifts, such as national and regional bioeconomy agendas such as the EU Bioeconomy strategy, are increasingly supporting the transition toward biomass and recycled feedstocks in the chemical sector, further reinforcing the shift away from fossil-based raw materials in products.

Leading the shift from fossil dependence to circular carbon solutions

For Perstorp, advancing circularity is not only a regulatory imperative, but a strategic pathway to remain competitive, resilient, and future-ready. By championing circular solutions, Perstorp helps reduce dependence on virgin fossil feedstocks, expand the use of recycled, bio-based, and CO₂-based feedstock, and minimize environmental impact throughout the product lifecycle.

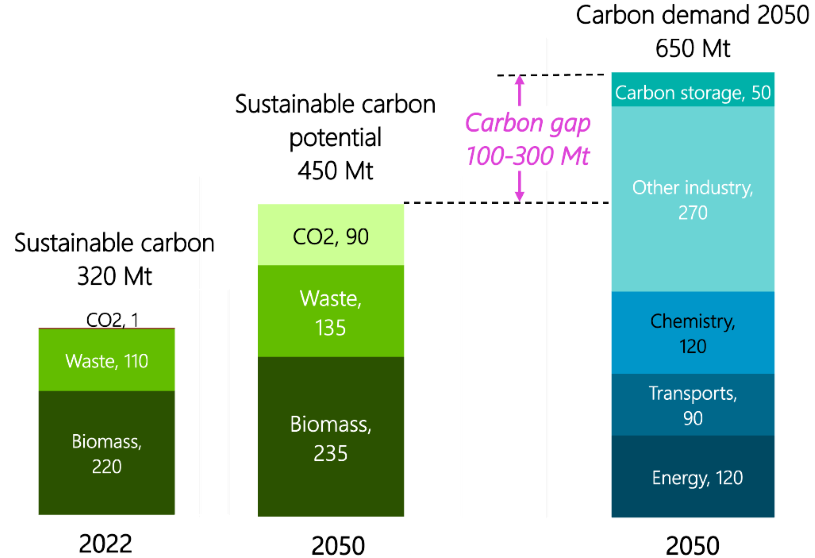

This shift is increasingly critical for the chemical sector, where raw materials and end-of-life treatment account for a large share of carbon emissions, often more than 80% of a product’s total footprint. Transitioning to alternative feedstocks (biomass, recycled waste and CO₂) therefore represents one of the biggest levers for carbon emission reduction, both for Perstorp and for our customers’ value chains. By advancing this raw material transition while developing circular and recyclable product solutions, Perstorp is able to unlock new markets, strengthen customer partnerships and contribute to a broader shift toward sustainable consumption and production.

Perstorp supports the chemicals industry transformation to circular material flows, e.g. through innovative products such as the Akestra™ high-performance polyester that enables PET recycling for hot-fill food packaging, as well as through our Pro-Environment Solutions. Pro-Environment are ISCC PLUS certified products that reduce CO₂-emissions and are produced from recycled and/or renewable raw material based on a mass balance with chemical and physical traceability that shift raw materials and reduce lifecycle emissions across the entire value chain.

Developments in the EU

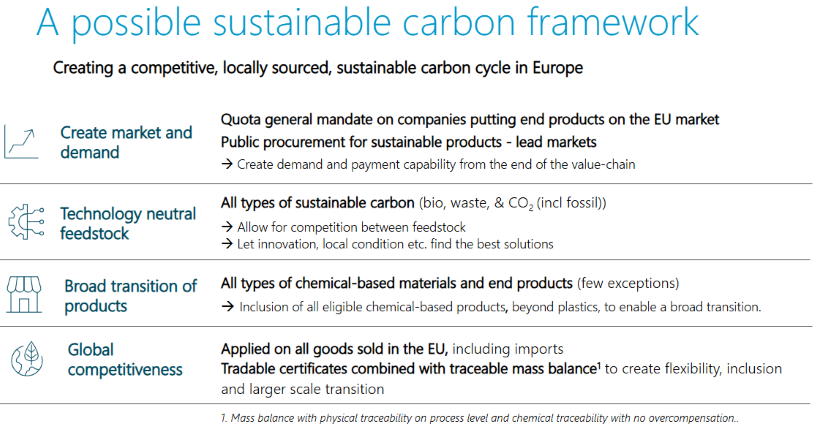

The most progressive work in replacing fossil raw materials is currently taking place in the EU, where a regulatory framework for sustainable chemicals and products is being developed.

Key to such a framework is to create a demand for sustainable products, that in turn creates market pull for chemicals such as Pro-Environment Solutions that drive the shift of raw materials all the way up the value chain. When sustainable carbon sources replace imported fossil raw materials, it strengthens EU’s resilience, it drives much needed investments, and it facilitates the green transition. That is a strong purpose.